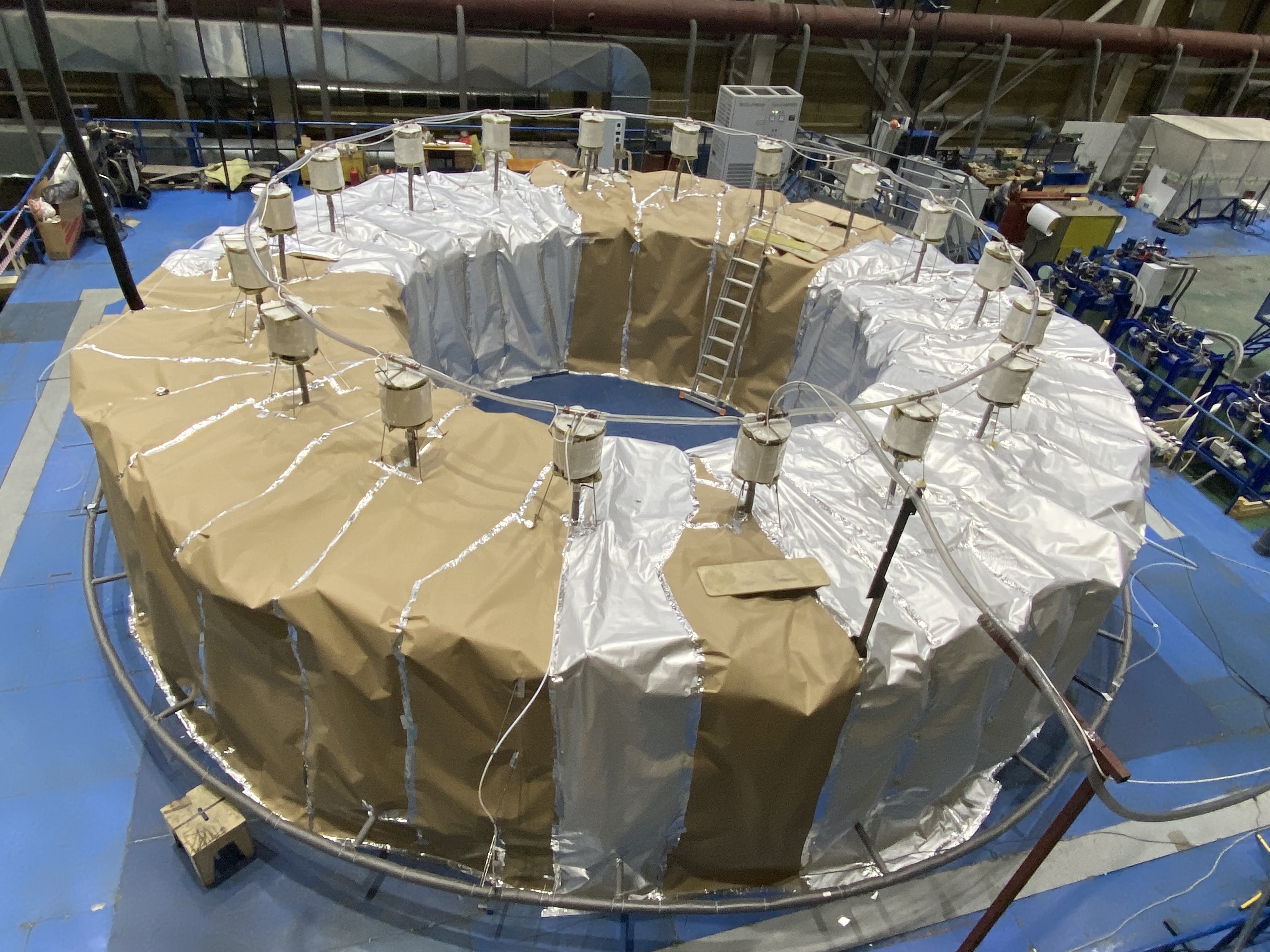

Poloidal Field Coil 1 for the ITER machine was successfully impregnated at the facilities of the Sredne-Nevsky Shipyard (SNSZ) in Saint Petersburg.

The Efremov Institute (JSC «NIIEFA», Rosatom) and Sredne-Nevsky Shipyard (SNSZ) specialists have successfully finished PF1 coil winding pack impregnation. Vacuum impregnation is a crucial stage of the PF1 coil manufacturing, which was preceded by a number of technological milestones completed last year.

Poloidal field coil 1, nine meters in diameter and weighing 200 tons, is one of six poloidal field coils in the magnetic system, designed for plasma confinement in the ITER machine. The Magnet is a complex system, the basis of which is two-layer double pancakes that consist of cable-in-conduit conductor basing on niobium-titanium superconductor, manufactured earlier in Russia (JSC «TVEL», JSC «CHMZ», JSC «VNIINM», JSC «VNIIKP»). It offers superconducting properties at super low temperatures about 4 Kelvin.

The manufacture of a poloidal field coil due to the uniqueness of the product and the extremely high requirements imposed by the ITER Organization, required the development and improvement of advanced technologies and technological processes. The most important technologies, as well as the equipment for manufacturing were developed at the D.V.Efremov Institute of Electrophysical Apparatus (JSC "NIIEFA").

Anatoly Krasilnikov, Head of the Russian ITER Domestic Agency said: «It’s hard to overestimate the importance of this stage of Russian poloidal field coil manufacturing. The main difficulty during the impregnation was an irreversibility of the operation; it would have been impossible to alter anything in case of failure. But we had no doubts that we would succeed, because a truly high-class team is working on the manufacture of the coil».

Vacuum impregnation of PF1 coil is necessary to obtain electrical insulation with extremely high dielectric and mechanical strength. The production of the PF1 coil will go through a number of the following technological operations in the future. Then, after final assembly, the system will be prepared for its shipment to the construction site of the ITER machine in the south of France in 2022.

Russian Poloidal Field Coil 1 for the ITER machine has passed a key manufacturing stage

Russian Poloidal Field Coil 1 for the ITER machine has passed a key manufacturing stage